Salescaster Smart Efficiency Systems

All-In-One system measures, records and analyzes Productivity

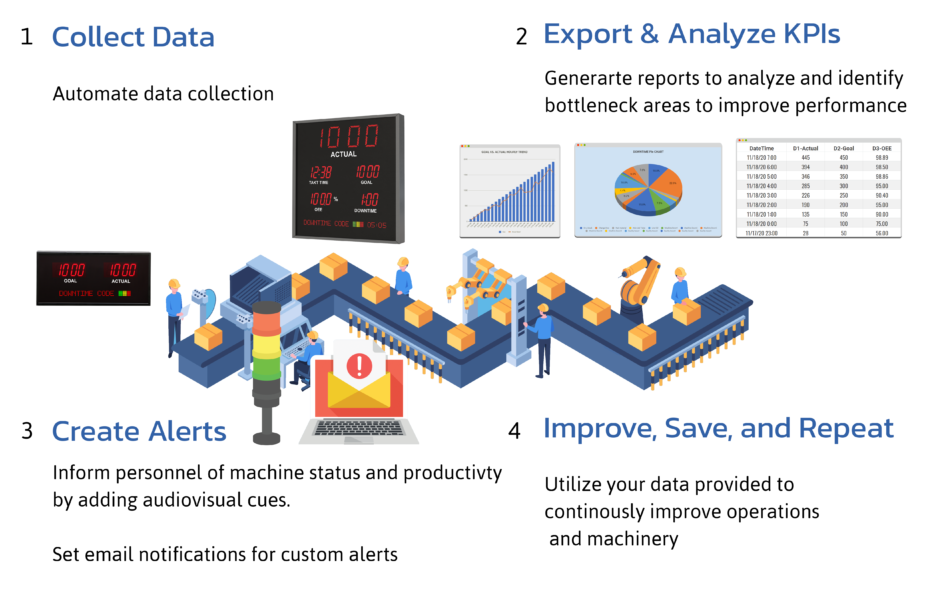

Every manufacturing operation has at least one area known as the Bottleneck. The Bottleneck is an area on the production line where any downtime will slow throughput and immediately reduce the company’s total productivity. A production line is only as fast and effective as its weakest point. Many companies invest heavily in different methods to improve their bottleneck throughput and overall productivity.

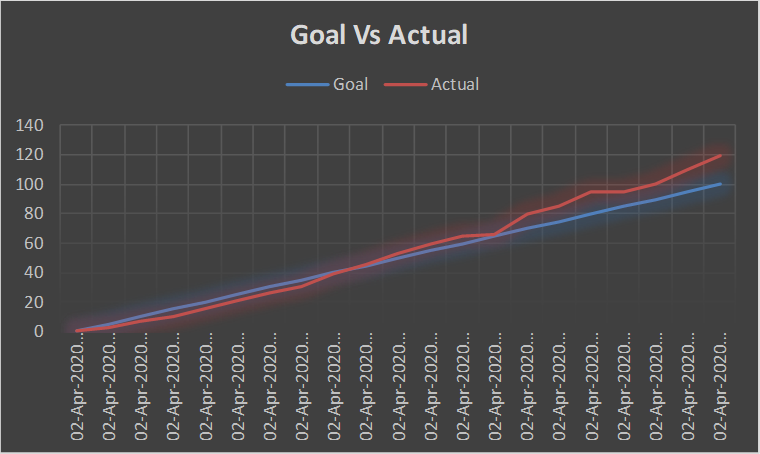

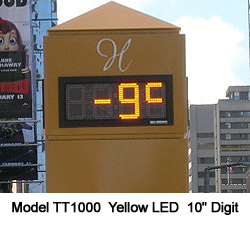

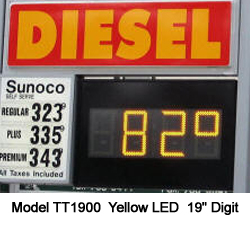

Salescaster Displays offers operation’s leaders an all-in-one Smart Efficiency Improvement System to measure, record, and analyze a product line’s downtime and productivity. The digital LED Counter may be configured with TAKT, Goal Count, Actual Count or any other information that needs to provide instant visual feedback. You may also customize the Efficiency System for remote viewing and historical data log when connected via USB or Ethernet.

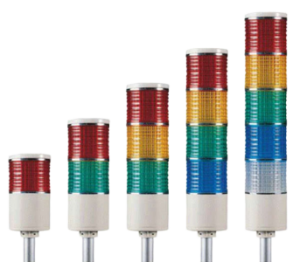

The efficiency timer display can also work as an alert system for scheduled breaks, unscheduled downtime or emergency alerts. If instant notification is vital, add a piezzo buzzer, alarm bell or Andon signal light to the display. Managers can also set up alert notifications straight to their email or phone via text.

Measure Data

Whether is it is remote control, push button, infrared sensors or PLC, you can choose how to measure and count data. You can keep a simply tally count of a production line or compare it to the day’s goal.

If a target is not being met, or if there are any issues causing downtime, instantaneously notify the entire production floor with any of the following audiovisual add-ons: flashing border lights, process timer Andon lights, external alarm bells, or internal Piezzo buzzer alarms.

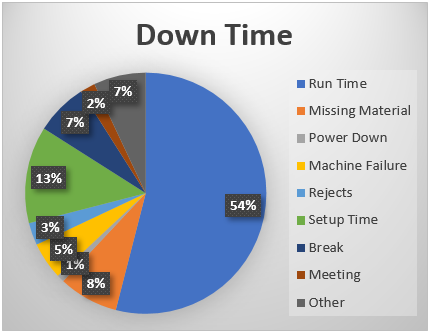

Record and Analyze Data

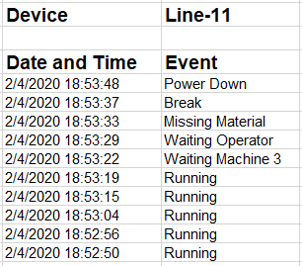

Our Smart Efficiency System allows up to 12 codes of alerts and message trackers. The 20-character message board allows for a variety of messages including: current date, down time reason, beginning or end of breaks, fire and weather alerts, and more. Convert the main TAKT timer to a downtime tracker with the press of a button or set up automatic alerts for scheduled shift breaks. Manage flow control by freezing the Smart Efficiency System during scheduled breaks and automatically restarting counts at the beginning of each day.

Our Smart Efficiency System allows up to 12 codes of alerts and message trackers. The 20-character message board allows for a variety of messages including: current date, down time reason, beginning or end of breaks, fire and weather alerts, and more. Convert the main TAKT timer to a downtime tracker with the press of a button or set up automatic alerts for scheduled shift breaks. Manage flow control by freezing the Smart Efficiency System during scheduled breaks and automatically restarting counts at the beginning of each day.

When there are multiple production lines spread throughout a factory, it can be difficult to aggregate feedback effectively. With Ethernet, operations leaders can access a secure Linux-based system interface through their company’s local network on any computer or mobile device to view live data of every device connected to the system. Our facility monitoring system also generates an excel of historical data as well as an event log for all triggered alerts.