Lean Manufacturing Principles and Salescaster LED Displays

LED Signs Enhance Lean Manufacturing and 6 Sigma Programs by Displaying Plant Efficiency Data and Overall Performance

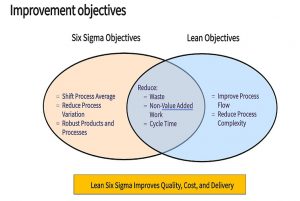

The principles of Lean Manufacturing created by the Toyota have become so widespread chances are you’ve heard something about them or are involved in some form of it. The idea is that one can divide their workforce into distinct processes or work cells that can be easily monitored. Companies with active Lean Manufacturing programs understand the need to map and measure every stage of their “Value Stream” for each product with the objective of eliminating waste from every process.

Analyze and Identify Bottleneck Areas

Need help analyzing the data? Salescaster Dislays offers lifetime customer support and premade templates.

Download up to 6 months of recorded data or approximately 40,000 lines on Excel.

Generate reports to analyze and identify bottleneck areas to improve overall performance.

Plant Efficiency Data

Overall Shipping Performance

KEY LEAN PRINCIPLES

1. Define value precisely from the end customer perspective.

– Specific product needs

– Specific capabilities

– Specific price, delivery and quality expectations

2. Identify the entire value stream for each product line and eliminate waste.

– Product definition and development

– Material transformation

– Information management

3. Make the value added activities flow.

– Through radical shifts in process methodology and organizational structure

– Improving processes from end-to-end by eliminating scrap, downtime and WIP

– Moving towards continuous operations vs. batch processing

4. Provide what the customer wants only when the customer wants it.

– Let the end customer pull products from the manufacturing value stream

– Minimize finished goods inventories and WIP

4. Pursue perfection through continuous improvement to the value stream.

– People recognize there is no end to reducing effort, time, space and mistakes

– Your products become more closely aligned with the customer needs.

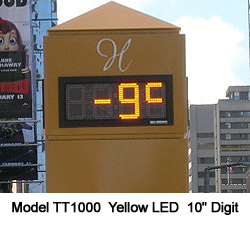

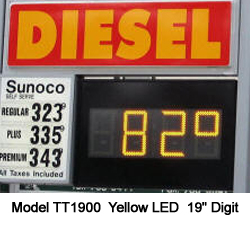

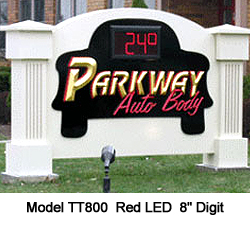

Salescaster LED displays improve the effectiveness of any Lean Program by giving you the ability to post these measurements where they are needed most by displaying Plant Efficiency Data and Overall Performance. Call 800 346-4474 for a fresh approach to Dynamic Visual Communication.